Quality management.

We carry out inspections in person, either by traveling directly to the factory or by transporting the rackets to our facilities in Zhuhai.

A quality service.

The main point on which we have based our career has been the importance we give to the quality control of our products.

A model based on quality control

Our method for quality control has been forged after more than 10 years of going back and forth to factories. All this experience has helped us realize that it is precisely in this tedious task where there was the most to do and where we should put the most emphasis for the good of our clients and for our own.

The keys to our method.

There is no secret, work, work and work.

Production monitoring.

Quality control begins from the moment production begins. Routine visits to factories are used to carry out quality controls and review the status of the units of the batches to come as they are manufactured and thus check that everything is correct. Instructions are given if necessary and the client is informed if any notable incident has been detected that could represent a delay in delivery dates.

Guarantee the status of production.

Once all production has been completed, a quality control is carried out on at least 30% of the entire order. We carry out these quality controls directly in the factory or having transferred part of it to our facilities. During quality control, a very strict method is followed in which a set of very specific data is taken note of for each unit, which has a unique code to be able to track it in the event of a future incident.

Taking care of the client’s interests.

A visual inspection of the general condition of the rackets is carried out and all those that do not meet our quality standard are removed. It has rarely happened to us but if a generalized incidence were detected we would be prepared to carry out 100% quality control, even going so far as to reject the entire batch if necessary. All units directly inspected by us are sealed and certified. Finally, a report with the result of the inspection is sent to the client.

We examine the quality of everything.

Our main product is rackets but of course we also provide all accessory materials, racket bags, backpacks, grips, protectors, wristbands, caps, footwear, even paddle tennis courts. And obviously, as it could not be otherwise, we apply the same zeal in the quality controls that we do with the rackets.

Something obvious but incomprehensibly not always taken into account is that the first and most important quality control is the availability of good suppliers. All inspections are of no use if the product is of poor quality.

More than a decade dedicated to quality management.

Take advantage of all the tools we put at your disposal.

Information is power and knowing how to manage and control data helps to improve in all aspects.

Detailed reports

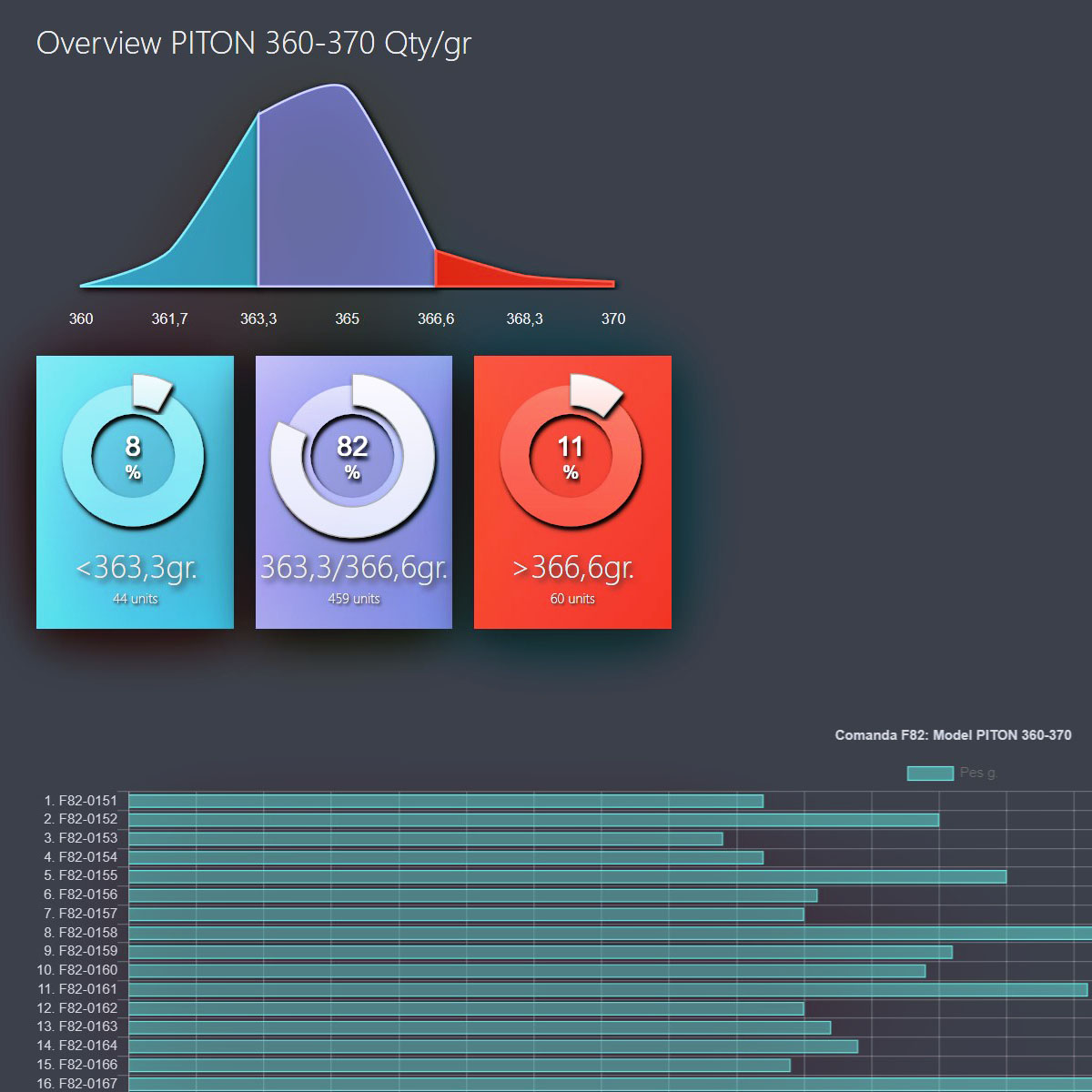

Rackets can be affected by a wide variety of defects. During quality controls, more than 30 elements present in the rackets are examined to ensure the perfect condition of each one of them. Everything is saved in our database for later analysis. We classify the data into three groups: technical, cosmetic and structural. Through an automatic process, the quality of the inspected order is determined based on the data collected and the batch is approved or not.

The usefulness of this data serves us not only to guarantee the customer the quality of the order but also, and this is very valuable, to maintain statistics related to production and quality over time.

And now let’s talk.

Tell us about your project. Share with us your idea for your brand, your concerns, your doubts. We will find a way to provide you with personalized solutions to all of them.