Production management.

We are based in Zhuhai, China. This allows us to personally manage the day-to-day production within the factories at all levels.

Stability and confidence in production

We have been cooperating with the same factories since 2010, which is why our presence inside the factory is essential to keep every detail under supervision and in this way check the progress and quality of the production line. This stability with manufacturers has contributed to improving confidence in production processes and resulting in improved product performance and quality.

Transparency with clients

Quality and consistency in production is important but the relationship with the customer is no less important. We want our customers to feel calm, to know at all times when, how and where the manufacturing of their raquets is being carried out and to be certain that there will be no unexpected surprises.

Preparations for production.

Once the collection has been confirmed by the client it is time for the factory. Starting a production is a process that is not done overnight. There are many preparations that must be coordinated to minimize any incident and for this to be the case, daily communication with the factory plays a very important factor. That’s where all our experience on the ground comes into play. We have a plan and we must execute it.

01

Designs

At this stage the collection has already been defined with the client, the models, their compositions and finally the designs are available.

Once the client formalizes the order we have to get going. There are several processes that begin in parallel. On the one hand, the designs of the cosmetics are sent to the decal supplier. We work shoulder to shoulder with him so that everything is adjusted to the millimeter just the way we want. Color tests are carried out as necessary until the desired tone and effect is obtained. We ensure that each element of the design is well positioned and that the quality of the prints is perfect. This entire process is done in close collaboration with the client to ensure that each color, logo and finish is in accordance with them.

02

PREPARATIONS

While working with the decal supplier, the factory is informed of our intention to start new production. The details of the models, quantities, compositions are passed and production periods are determined, ordering the restructuring of our molds on the table if necessary.

We permanently have more than 20 molds on the table in constant production. This allows us to not have to wait to start manufacturing for our customers.

In this phase the factory purchases all the necessary material to carry out all the production and to make the first samples that will allow us to see that everything is as expected. If there are several versions for the same model, it will be time to confirm which design is chosen.

03

MANUFACTURING

When the samples have been approved, we are ready to start manufacturing. In this phase, communication with the factory continues to be very important to ensure that everything goes as planned and that there are no incidents. Routine visits are used to carry out quality controls to review the status of the units as they are manufactured and check that everything is correct. Instructions are given if necessary and the client is informed if any problem has been detected that could represent a delay in delivery dates. The only objective is to ensure the quality of the product.

All our rackets are manufactured in China. There are very important factors that you should know and understand about the Chinese manufacturing method that makes our products of the highest quality and that require a separate explanation.

04

QUALITY CONTROL

Once all production has been completed, a quality control is carried out on at least 30% of the entire order. We carry out these quality controls directly in the factory or having transferred part of it to our facilities. During quality control, a very strict method is followed in which a set of very specific data is taken note of for each unit, which has a unique code to be able to track it in the event of a future incident. A visual inspection of the general condition of the rackets is carried out and all those that do not meet our quality standard are removed. It has rarely happened to us but if a generalized incidence were detected we would be prepared to carry out 100% quality control, even going so far as to reject the entire batch if necessary. All units directly inspected by us are sealed and certified. Finally, a report with the result of the inspection is sent to the client.

About the Chinese construction method of padel rackets.

Construction.

There are very important details about the manufacturing that makes our rackets, made exclusively in China, of the best quality that exists on the market. Without discussing whether the rackets manufactured in one country or another are the best or not, we do want to make known a primary factor that makes both the finishes of our rackets and their structural quality top-notch and that is the pre-impregnation of all its fibers.

What is pre-impregnated?

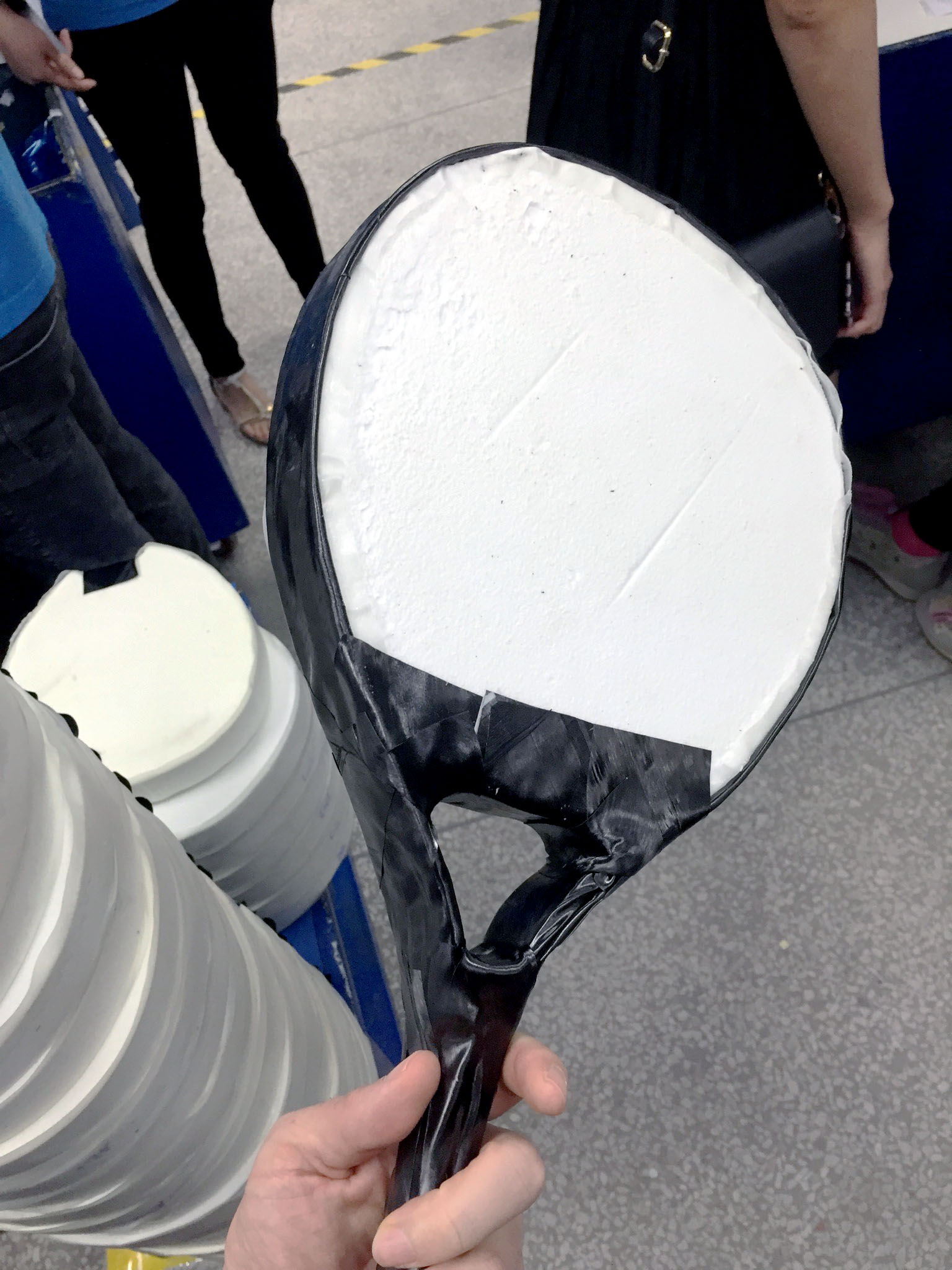

The rackets are made with pieces of carbon fiber or fiberglass to make not only the frame but also the external fibers of the face of the racket. All these fibers must be impregnated with epoxy resin in order to achieve a solid structure during the baking process inside the mold and this is where our rackets differ from the rest, since all our fibers come mechanically pre-impregnated instead of applying the resin with a brush like many other manufacturers do. It is to be expected that the work done by a machine will always be more precise than what an operator can be with his brush. Thanks to the impregnation machine we ensure that all our fibers have the same amount of resin per cm² always obtaining an absolutely homogeneous finish, avoiding any possible weak point, with the consequent benefit in terms of weight control and quality control of the finishes.

The assembly

In addition, the pre-impregnation also affects the assembly of the raw rackets. In our case, all the rackets are completely assembled in a room specifically prepared with specialized technicians who are only dedicated to placing each piece in its place and one after another all the rackets are accumulated to be transferred to the molding room. On the other hand, in factories that do not use pre-impregnation, the molding room operators are in charge of placing the fibers on the mold, impregnating them with the brush, assembling the tubular for the frame inside the mold, then arranging the EVA and continue with the other half of the fibers using the brush again to apply the epoxy resin.

Double tubular EVA

The double tubular is another factor that results from assembling the rackets separately. We do not use tubular meshes but the frame is manufactured piece by piece, which allows us to manufacture a double tubular that we also fill with EVA, which improves resistance and allows the EVA core to expand to a greater extent, considerably increasing the sweet spot. The difference between the two methods is highly significant since the specialization of the processes will always result in an increase in quality.

Quality of raw material.

Regarding the qualities of our carbon fibers and glass fibers, we have no doubt that we are also at the forefront, having as our main supplier one of the main Taiwanese manufacturers in the industry, who in turn is also the supplier of carbon fibers of important Italian and German luxury car manufacturers among others.

We want to emphasize that the product coming from China is too often and lightly despised and we must know that currently, China, years ago, stopped being the cheap, low-quality manufacturer that many people still have in mind to become an industrial power in terms of innovation and high-end product.

Once production has started, one of our main jobs and where we have made the most effort from the beginning is in managing the quality of our rackets and products. Keep reading and we’ll explain how we do it.